The JJ’S brand originated from my own need for suitable and functional sleeping bags and clothing for my baby. Because I didn’t really find what I was looking for in the shops, I started sewing myself.

The requirements that the clothing had to meet were extremely high. In the first place, the clothing had to be super soft. So soft that it could provide all comfort that the soft and sensitive skin of my baby needed.

Secondly, my baby had to look beautiful. The fit had to be good, easy to dress and undress and it had to fit comfortably so that my child wasn’t restricted in his movements.

Finally, the clothing was allowed to contain absolutely no chemical residues. As a pharmacist, I know well how harmful the remains of chemical processes, paints and pesticides are. Harmful chemicals are needed to keep clothing ‘fresh’ for months in a dusty warehouse in (sub) tropical countries with a humid climate.

Ik mocht er niet aan denken dat de huid van mijn babytje hiermee in contact zou komen

As a fledgling mom, I was more than ever aware of the comfort of our Western society. The maternity leave, was more than necessary after giving birth. And it took time to adapt to a new life with a baby. A child also brings unexpected costs.

So when I started looking at production possibilities, a correct wage and European working conditions were an absolute necessity to which I would never make any concessions.

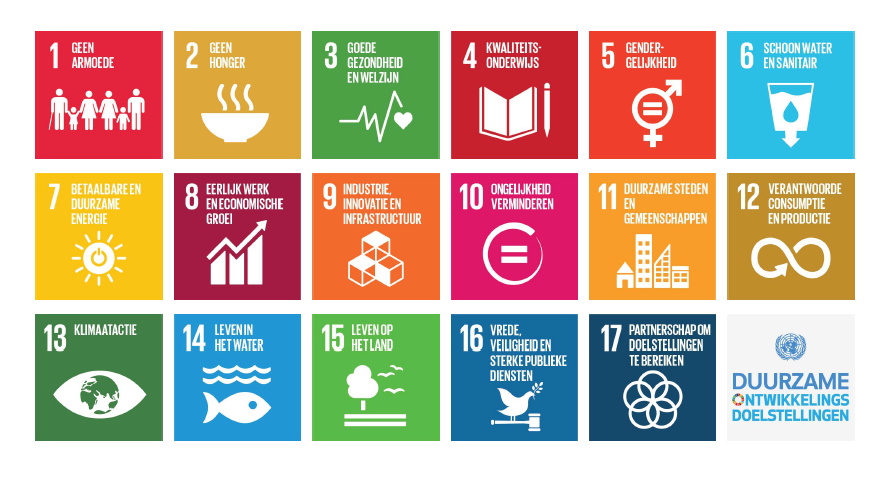

In my opinion the clothing had to be beautiful, comfortable and wearable and made with respect for people and nature. When setting up my company, I wanted to implement the 17 Sustainable Development Goals.

Implementing the 17 SDGs in your company is going for the highest level in all areas.

I started my search for a suitable material. I would only accept the highest quality. When I discovered bamboo, I found a material that meets all my strict requirements.

I wanted to set up a production that was as ecological as possible. Bamboo is grown organically in a natural way. It is weeds, you can’t get rid of them. It grows luxuriantly without additional water irrigation, requires no fertilization and does not require pesticide use. Bamboo can also be grown all over the world. Bamboo is fully grown after 4 years. The bamboo sticks are cut just above the ground. After the harvest, it grows back agian. In this way no giant plantations are needed and soil erosion is prevented.

“Wear bamboo, reduce co2”

Bamboo converts 30% more CO2 than other plants and trees. Increasing bamboo cultivation has a direct positive effect on our climate.

Our clothing is made from the best quality bamboo viscose. We process our bamboo sticks by the Ecovero viscose process. In this way we keep the impact on the environment as low as possible. No harmful chemicals or wastewater is released during production. We obtain the pulp from Lenzing in Austria. This is transported to Portugal. Here everything happens in a radius of 100 km. The bamboo pulp is spun into yarn by dry spun. No more water is involved.

The yarn goes to the weaver and is woven into a Jersey or satin. The dyeing is done as ecologically as possible, here we opt for eco dying, but also for a quality that prolongs the durability of the garments. The weaver does a finsishing on the material that prevents pilling. Again, no chemicals are involved, and the lifespan of the garment benefits. The clothing is also fully recyclable. You can simply put it in the compost bin

Bamboo also has the characteristic that it is very soft and pleasant to wear. It is anti-allergic and has antibacterial properties. This makes it extremely suitable for high sensitive children and children with difficult (eczema) skin. Due to the antibacterial properties, the clothes stay fresh for longer and can be worn for several days. Bamboo has good heat regulation and absorbs four times more moisture than cotton

Voor de productie van onze kleding werk ik samen met een klein naaiatelier in de buurt van Porto in Portugal. Ik maak de ontwerpen en patronen in Belgie, zij voeren ze uit. Door het persoonlijke contact kan ik erop toezien dat de werkomstandigheden goed zijn en dat deze mensen naar behoren worden betaald. In Portugal weet je dat iedereen betaald wordt voor wat hij doet. De lonen liggen nog net iets lager dan in Blgië maar qua levensstandaard is dit goed

Omdat het hele verhaal moest kloppen werken we uitsluitend met 100% gerecycleerde verpakkingen. Onze hangtags, flyers, catalogus zijn gemaakt uit 100% gerecycleerd papier. Voor het transport wordt onze kleding niet langer verpakt in plastic, maar in gerecycleerd zijdepapier en dozen van recycling karton. Particulier bestellingen via de webshop worden verzonden in gerecycleerde plastic verzendzakken.

I make the designs and patterns in Belgium. For the production of our clothing, I work with a small stitch factory near Porto in Portugal, where we make the prototypes together and do the productions

Thanks to the personal contact, I can ensure that the working conditions are good and that these people are properly paid. In Portugal you know that everyone is paid for what he does.

Because the whole story had to be right, we only work with 100% recycled packaging. Our hangtags, flyers, catalog are made from 100% recycled paper. For transport, our clothing is no longer packaged in plastic, but in recycled paper and boxes made from recycling cardboard.

Private orders true the webshop are sent in recycled plastic shipping bags.

For production we only work with partners who work under the following certificates: Oekotex100, Fairtrade, FSC.

I do not participate in fast fashion. We do not go for 2 collections every year. We design new pieces that are added into the collection, others go out.

Also for the colors, we look for a collection that can last for several years. This is how we want to make the difference with fast fashion.